Water treatment

We have extensive experience of water purification projects and can offer expert advice for all types of water. Our modern and easy-to-use water treatment plants can be tailored to meet all the site-specific challenges a project can offer. We take responsibility for the establishment and de-establishment of the facilities and perform service and operational inspections in all our water treatment projects.

For water purification, where the challenge includes particles and particulate contaminants, Envytech offers flexible solutions that include everything from automated precipitation and flocculation as well as pH adjustment to sediment containers and easily maintained lamella separators. We design systems for all types of capacities, from low to high flows >100 m3/h.

For water polluted with dissolved metals, organic pollutants and PFAS, we offer mobile easy-care and winter-proof filter systems, which can be equipped with filter mass as required. Organic pollutants are often treated effectively with activated carbon filters and dissolved metals with ion exchange compounds. These units can also be designed for all types of flows, and can easily be connected to our particle separation systems for water with both particle and pollution problems. For purification of PFAS, both ion exchangers and carbon can be used, but also the new sustainable technology SAFF – Surface Active Foam fraction, where PFAS is purified using air. Which method that is best suited depends on the type of PFAS substances, the type of flow and the schedule of the project. As Envytech drive the development of purification techniques for PFAS in Sweden, we provide system designs that offer the most effective solution for your particular PFAS pollution, both from an economic, practical and environmental stand point.

All our solutions (including SAFF) can be connected into efficient treatment trains, which can handle all types of pollution and challenges that may arise. As water is changeable, so must the treatment plants be. We are used to handling all types of pollution and offer all treatment plants from our own fleet and both perform and interpret analysis results. Therefore we can quickly adapt our facilities in cases where our customers’ needs / water change, which has led to us becoming a trusted and valued partner in the industry.

Treatment Systems

Sedimentation Containers

Lamella Separators

Water Treatment Containers

Mixer Tank

Filter Container

SEDIMENTATION CONTAINER 35–38 m3

Envytech’s sedimentation container is based on a de-mountable container and is 35-38 m3 in size. The sedimentation container has four separating walls and two water underpasses. Depending on the quality of incoming water, the lamella separator needs different amounts of control and care. We recommend weekly inspections of normally polluted water, but a daily inspection in cases where it is possible. With normally polluted water, an emptying frequency of 2–4 weeks is normal. During periods of turbid water with a lot of particles, weekly emptying may be needed.

Emptying is performed using a suction truck. In cases where it is possible, the material from the emptying can be returned to non-decontaminated areas to minimize the cost of removing material. In cases where it is possible to influence the amounts of suspended material that reach the separator, this should be done. This is because by minimizing the amounts of suspended material into the equipment, the need for cleaning, supervision and emptying can be minimized.

Prior to establishment, a suitable surface is required for setting up the equipment with access to electricity in case winter protection is required (16 A). The area should cover about 20 m2 (4 × 5 m).

| Dimensions | |

|---|---|

| Width | 1450mm |

| Length | 3800mm |

| Height | 1800mm |

| Weight | 1960kg |

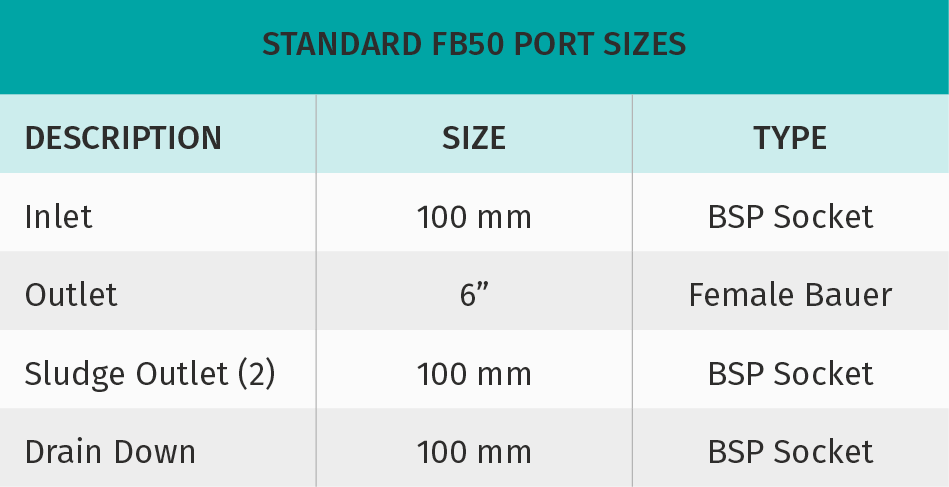

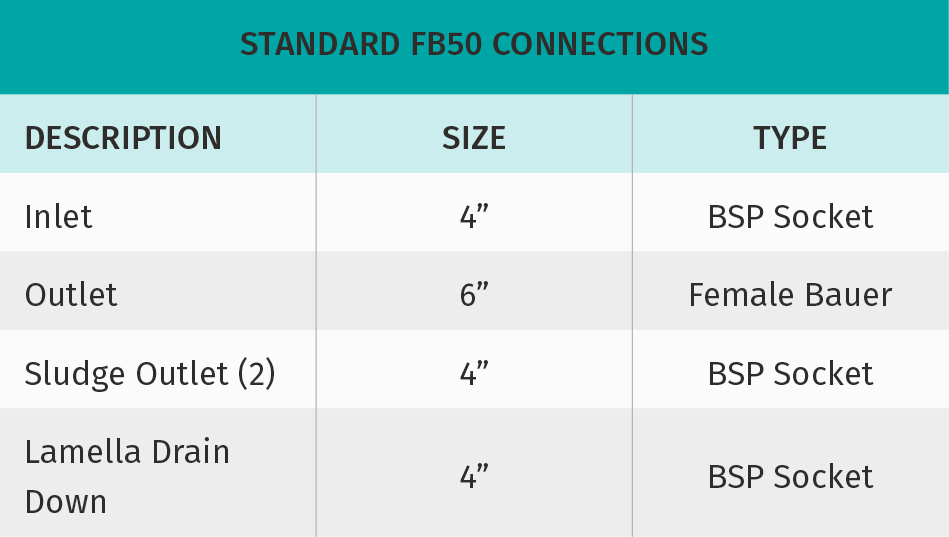

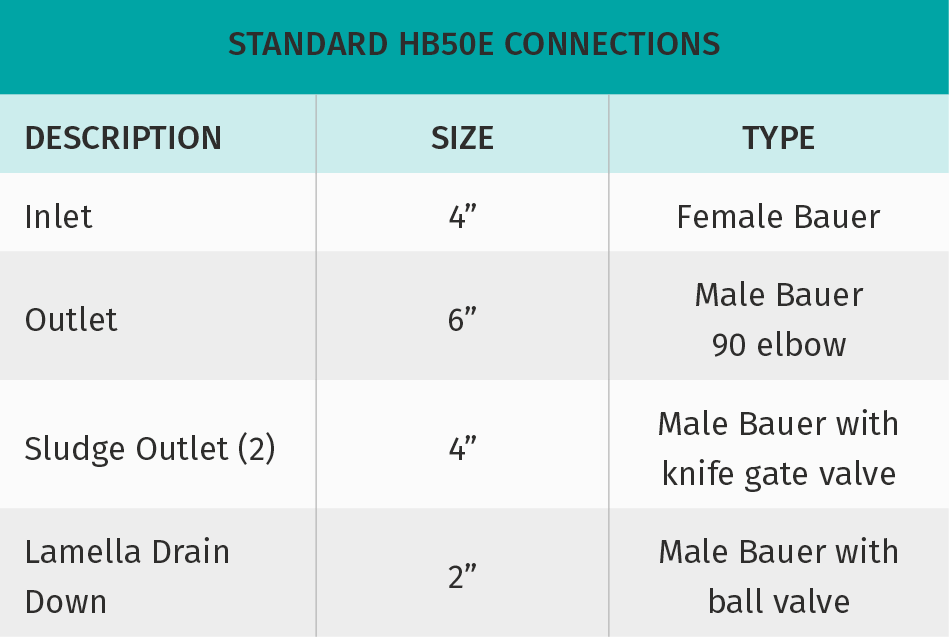

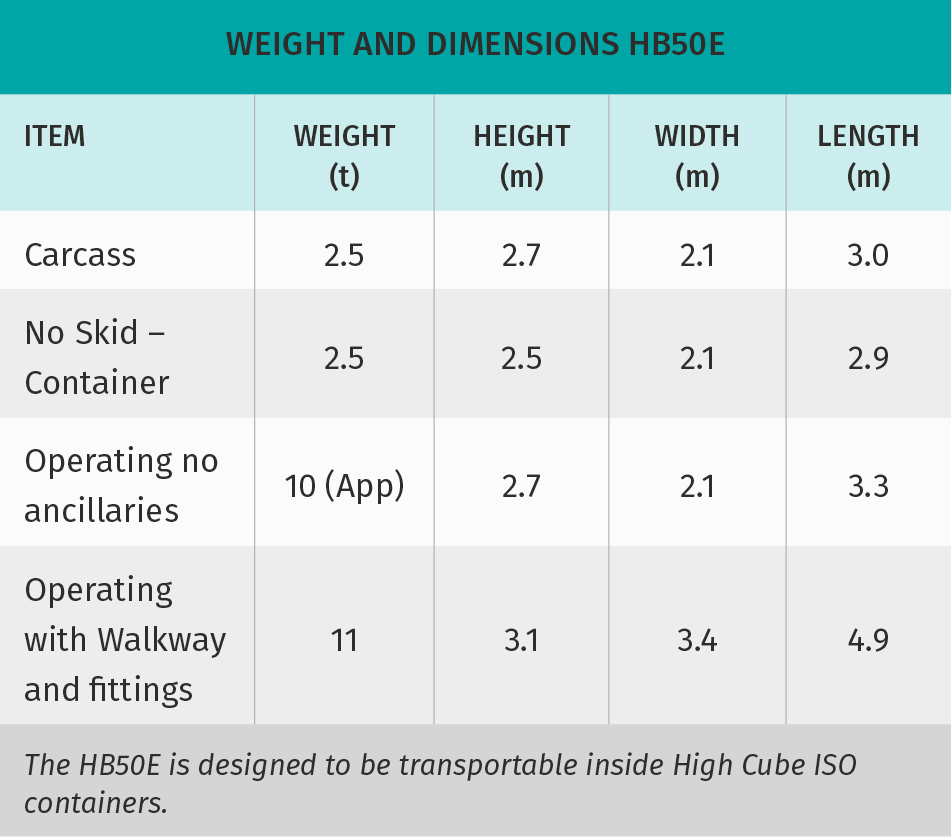

LAMELLA SEPARATORS – MODEL FB50/HB50E

Siltbusters lamellar separators are efficient particle separation units for all types of water. The units are designed to achieve over 90% removal of particles >15 μm in diameter (median size of particles in silt) at a flow rate of 45 m3/h, >10 μm at 20 m3/h and particles larger than 6 μm at 5 m3 /hr.

In normal use, the unit also works for the removal of the majority of particles in the 2-15 μm size class (fine to medium size silt particles). The capacity of the facility includes flows up to 50 m3/h.

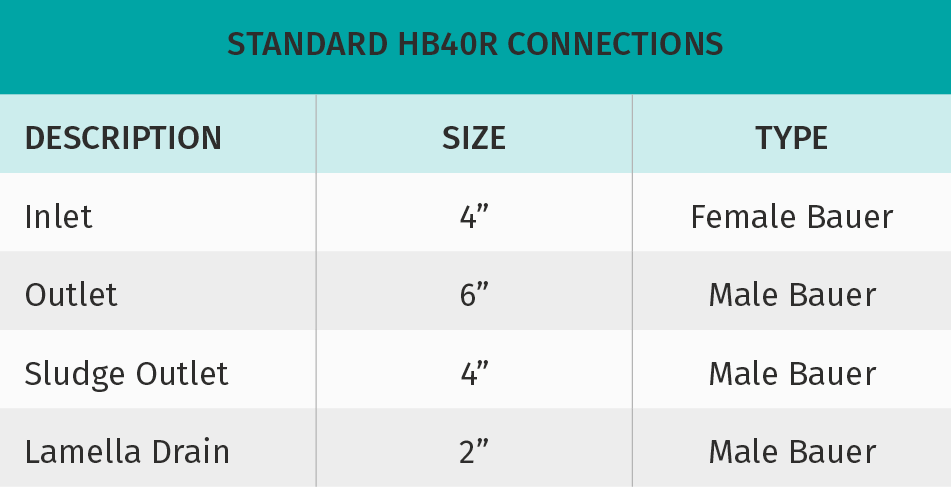

LAMELLA SEPARATORS – HB40R

WATER TREATMENT CONTAINER 4–8 m3/h

The unit consists of a 20-foot isolated pollutant treatment plant.

- A 1600 liter buffer tank for raw water

- Two bag pressure filters of type EF5

- Three filter columns of type FNS 130

- Compressor

- Heat

The pipe system is made of PVC and the filter columns are backwashable. The filter columns can be filled with a variety of filter media, such as activated carbon, sand and ion exchange mass. As all parts of the system are built into the insulated container, which is equipped with a heater, it is able to purify water at all temperatures. The recirculating sedimentation tank prevents coating and fouling in the tank, which saves on filter capacity. The facility is equipped with clear pressure and flow meters, so it is easy to follow current pressures and flows in all parts of the facility.

WATER TREATMENT CONTAINER 3-5m3/h

The facility consists of a 10-foot insulated unit for treatment of contaminated water.

- A 650 liter buffer tank for raw water

- Two bag pressure filters of type EF5

- Two filter columns of type FNS 130

- Heat

The pipe system is made of PVC and the filter columns are backwashable. The filter columns can be filled with a variety of filter media, such as activated carbon, sand and ion exchange mass. As all parts of the system are built into the insulated container, which is equipped with a heater, it is able to purify water at all temperatures. The recirculating sedimentation tank prevents coating and fouling in the tank, which saves on filter capacity. The facility is equipped with clear pressure and flow meters, so it is easy to follow current pressures and flows in all parts of the facility.

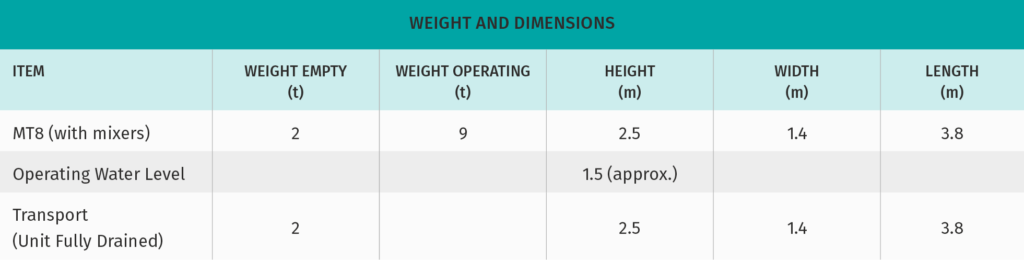

MIXER TANK – MT8

The mixer tank is used for the addition of precipitation and flocculation chemicals as well as PH-adjusting agents. These are added to purify the water from particles (susp.). The additive means that the water is effectively cleaned of particles, even fine particles with a long settling time. PH adjustment is performed with carbon dioxide (CO2) or hydrochloric acid (HCl). Dosing takes place automatically via external control cabinets.

FILTER CONTAINER – QMAX

The 20-foot filter container has doors on both the short and long side for easy access to the equipment. Three hatches on the roof for filling and emptying media in the pressure filters. Insulated in walls and ceiling and floor are covered with stainless colander.

- Air heater

- Lighting fixtures

- Internal electrical outlets

- Flange connections for inlet/outlet

- Recess for electrical connection

Pressure filter

Three pressure filters in composite, of which one is diameter 1200mm and two are diameter 1400mm. The filters are equipped with manual and automatic valves DN65/DN80 for backwashing.

Booster pumps (Grundfos Hydro)

Three stainless pumps linked together to manage the operation of the filters automatically. One pump is run in normal operating mode and the others are used for automatic backwashing of the system when pressure differences between the filters occur. The water is led through strong HDPE pipes throughout the system.

Control system

- 2x Flow meters

- 4x Pressure sensor

- Siemens S7-1200 PLC

- Phoenix terminal block

- 7” Touch screen

- EWON for remote control

- 3×400 VAC