PFAS Treatment and remediation – water

For PFAS-contaminated water, both ion exchangers and carbon can be used, but also the new sustainable technology SAFF -Surface Active Foam fraction, where PFAS is separated from the water using air. Which method that is best suited depends on the type of PFAS substances, how big or small the flows are and the type of water. Envytech drive the development of purification techniques for PFAS in Sweden, and we design systems that offer the most effective solution for your particular PFAS problem, both from an economic, practical and environmental perspective.

SAFF – Surface Active Foam Fractionation

Envytech offers the SAFF – Surface Active Foam Fractionation technology, created by OPEC systems. The first sustainable treatment method for PFAS- contaminated water. SAFF does not use filter materials, only air and electricity, and is completely unaffected by other pollutants such as metals or organic substances, particles, pH, nutrients or other water chemistry.

STEP 1

The SAFF process utilizes the physio-chemical properties of PFAS compounds to attach to fine air bubbles as a result of its hydrophobic and hydrophilic properties. When accurately controlled bubbles are introduced and allowed to rise in a narrow column of water, the bubbles become exceptionally effective in collecting PFAS compounds that are loosely bound to the water molecules. Once at the surface, PFAS can easily be removed by separation and concentration through a passive ”spill over weir” system, and an active vacuum system. Treated (aerated) water can then be released to the recipient. The collected PFAS concentrate is passed on to further fractionation steps to become a high concentration liquid of relatively small volume suitable for destruction via permanent destruction techniques such as high temperature thermal combustion, Super Critical Water Oxidation (SCWO) or Electrochemical Oxidation (EO).

The system has significant advantages compared to all other technologies on the market as the process is very robust. SAFF works without reduced effect, regardless if the water contains large amounts of suspended solids and contaminants of various kinds, including oil and biological substances. The system is not sensitive to high concentrations and is not pH sensitive. The system is not in need of any pre-treatment systems, but to minimize service work, water comprising larger suspended particles can advantageously pass via some form of separation e.g. a lamella separator.

The SAFF system works by accumulating the PFAS compounds at the top of the first treatment column where the first fractionation step takes place. When air is injected at the bottom of the column and rises in a created vortex, the PFASs attach to the bubbles and flow with them to the surface. Foam and water flow over a “weir design” at the top of the column (see figure 2) and therefore called ”the wet cut”, as both the created foam and the underlying water are removed. This underlying water is removed as PFAS stratifies at the top of the column as the shorter chain PFAS do not have the same foam potential as the longer chains.

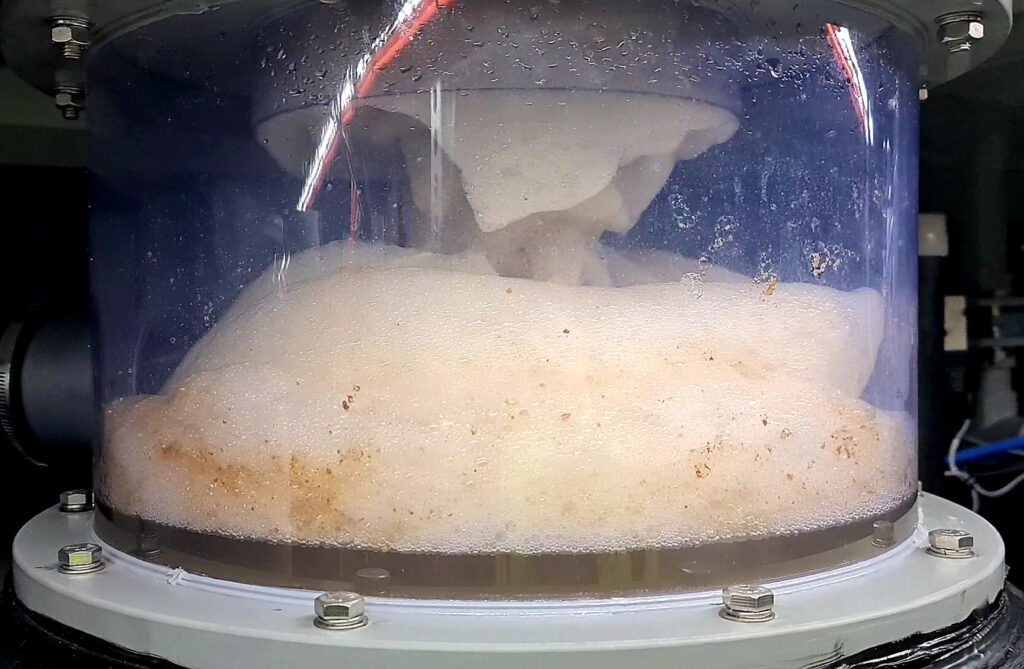

Figure 2: Photo taken during the execution of the first fractionation step in a full-scale plant. We see how in the first step you let foam “flow” over the edge of the centered inner tube in the column. You can also see the foam that accumulates during the separation and the top water where the less foam-prone PFAS substances accumulate.

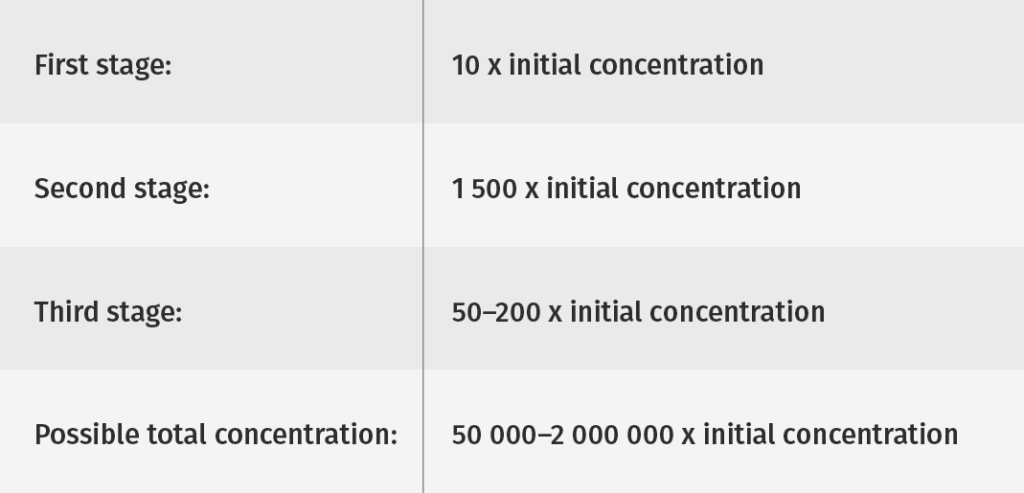

Before the end of the first fractionation step, the water level in the column is raised, forcing the water in the top of the column to be collected, so that as much of the stratified PFAS substances as possible are included in step two. The first fractionation step increases the PFAS concentrations by about 10-fold.

STEP 2

In the second fractionation step, the same process takes place as in step 1, but as concentrations of PFAS are now around 10 times higher, a drier foam is obtained which is removed with vacuum. The vessel where the second fractionation step is performed is equipped with carefully calibrated sensors that control a vacuum pump and its distance to actual process foam levels. The hyperconcentrate generated by this process is led to a collection container where it is stored pending step 3. In this second fractionation step, the concentration is further increased by up to 1,500 times, which means that the total concentration increase is now around 10,000 times initial levels.

Figure 3: Photo taken during the second fractionation step in a full-scale plant. The dry foam can be seen being removed by vacuum.

STEP 3

In the third fractionation step, which is performed in the same way as step 2, further concentration increases are obtained. The total increase in concentration obtained over the three steps is between 50,000 – 2,000,000 times initial concentrations in the untreated water. The hyperconcentrate waste volumes are therefore this same factor less than the processed feed water volume. Expected amounts of waste depend on the type of water that is treated, but from projects carried out we see that the expected amount of waste for landfill leachate are less than 1m3 per 40,000m3 of treated water, and for groundwater about 10 liters per 40,000m3 of treated water.

The table (below) summarizes the concentration increases at each stage:

EXPECTED RESULTS

To date (Oct 2021), 3 full-scale projects comprising PFAS have been carried out with SAFF. OPEC Systems has treated PFAS-contaminated groundwater using a SAFF system for over 2,5 years at an active military air base in Australia where extensive fire drills have been carried out. In total, more than 60,000m3 of water has been treated during this period, which has included drought times. Outgoing water has never exceeded the levels of Australia’s drinking water guidelines. In Södertälje, Envytech is treating leachate from the Telge Landfill, and since February 2021, more than 90,000 m3 of water has been treated down below treatment targets. Envytech is also treating leachate at the NSR landfill in Helsingborg where approx. 10,000 m3 of water has been treated since August 2021.

All projects have been carried out without pre-treatment systems or filter materials. Treatment results using SAFF are similar regardless of which water is put through the system.

CAPACITY

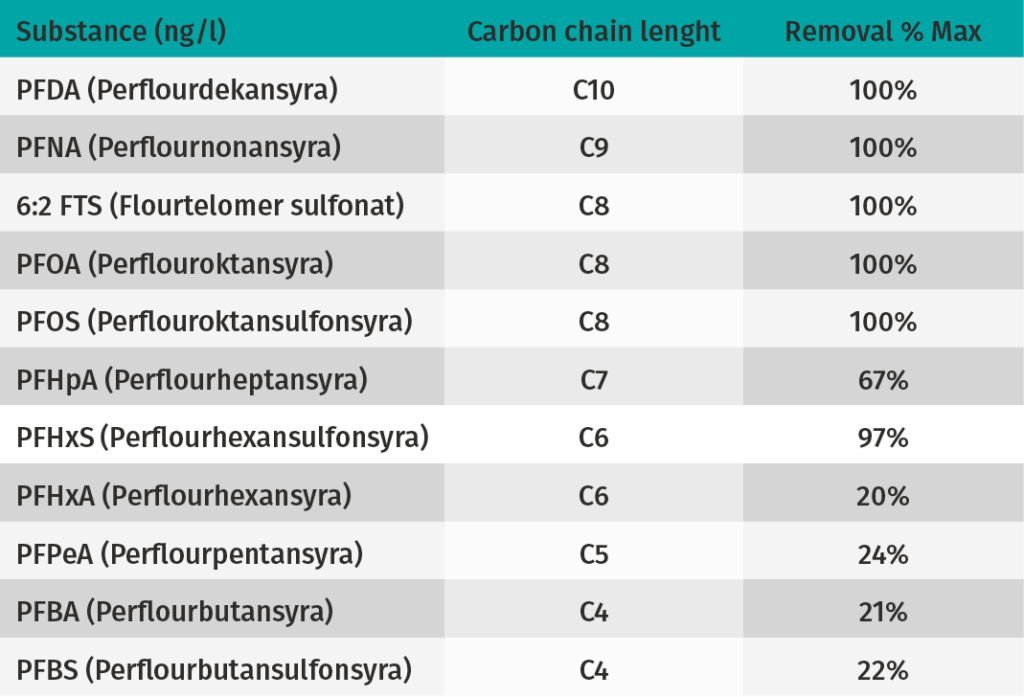

The capacity of a 40-foot SAFF40, with the possibility of three fractionation steps and internal storage of hyperconcentrate, depends on the type of water you want to and treat and PFAS concentration blend. This is because different PFAS require different cycle times, and the water’s potential to foam determines how much energy the pumps need to provide. From experience we see that a SAFF40 can treat leachate with a capacity of 20-40m3/h subject to the water’s tendency to foam, while for groundwater it is possible to treat about 40m3/h with the same equipment and a focus only on PFAS substances with 6 carbon atoms or more (<C6). When treatment of shorter chain substances is required, longer batch treatment times may be needed, which results in reduced flow capacity. Envytech also offers SAFF20 systems with a maximum capacity of 20 m3/h.

COST

The cost for treating water is usually made up of the following:

Mobilization

Mobilization includes transport of equipment as well as deployment and commissioning of the treatment system. This can be carried out in 2–3 days, including fine tuning of the system.

Pre-treatment

As SAFF is an extremely robust technology that takes advantage of PFAS strong bonding ability to air, no pre-treatment is usually needed, but for water with larger suspended particles, a lamella separator or other particulate separation can be used to minimize the need for cleaning during operation. (An existing filtration system, if it exists on site could be utilized).

Consumables

The operating cost for SAFF20 and SAFF40 are between 0.4–0.7 kWh per treated cubic meter of water. As different PFASs require different cycle times, the costs vary per cubic meter. For shorter chains, longer cycle times are needed resulting in less throughput, leading to slightly higher treatment costs. For the longer chains (C6 and above), shorter cycle times are needed as well as less energy per m3 treated. Costs for service work at a SAFF treatment plant are minimal. This is because all pumps, valves and sensors are connected to a digital monitoring and logging program where Envytech and OPEC can follow the plant’s operating and power data. In the event that a fault is noted with a pump or valve, we immediately get informed and can rectify this, often through adjustments in the made remotely, or alternatively a site visit is arranged. Therefore, routine service visits can be less frequent, thus reducing the overall service costs. The system is also easy to operate, a so-called ”Plug and play” system, and we can train the client’s own staff for ongoing supervision, operation and care, as required.

Waste

The SAFF system produces minimal amounts of waste due to the patentated tripple fractionation process, repeating the initial foam fractionation step twice. By doing this, the waste produced contains minimal water content, minimizing the waste volume and creating a PFAS concentrate. Waste Volumes for groundwater have been recorded to approx 15 liters per 50 000 m3 treated water, and for leachate to 200-1000 liters per 30 000 m3 treated. The PFAS concentrate can be destructed by thermal incineration, super critical water oxidation (SCWO) or electrochemical Oxidation (EO).

All components are sourced from the agricultural / construction / processing industry and are available from regular spare part dealers, and care has been taken to use European specification parts. In the event that something breaks, this means it can be readily sourced locally; no wearing parts need to be specially adapted or specially ordered.

Read about our case studies:

Swedavia

Telge

Red about:

SAFF and Soilwash

Filter solutions, carbon and ion exchangers

Envytech offers efficient and modern filter systems for all pollutants, including PFAS. The systems comprise columns of different sizes, where the desired filter material can be installed and where the size of the column depends on the flow handled.

When groundwater or process water is to be purified, filter steps with sand or glass media for particle branching may be sufficient, and then 1-3 columns with carbon or ion exchangers, depending on the current PFAS signature. When purifying surface water, leachate, wastewater or similar more complex water, where both particles and other contaminants can be found, filter columns should be preceded by pre-treatment such as lamella separators and / or steps with precipitation / flocculation, in order to increase the filter mass effect and life-span.

Envytech offers a complete design comprising both pre-treatment systems, recommendations and selection of filter media as well as the size of the set-up to obtain the most economical and efficient purification process.